From Development to Delivery

Products

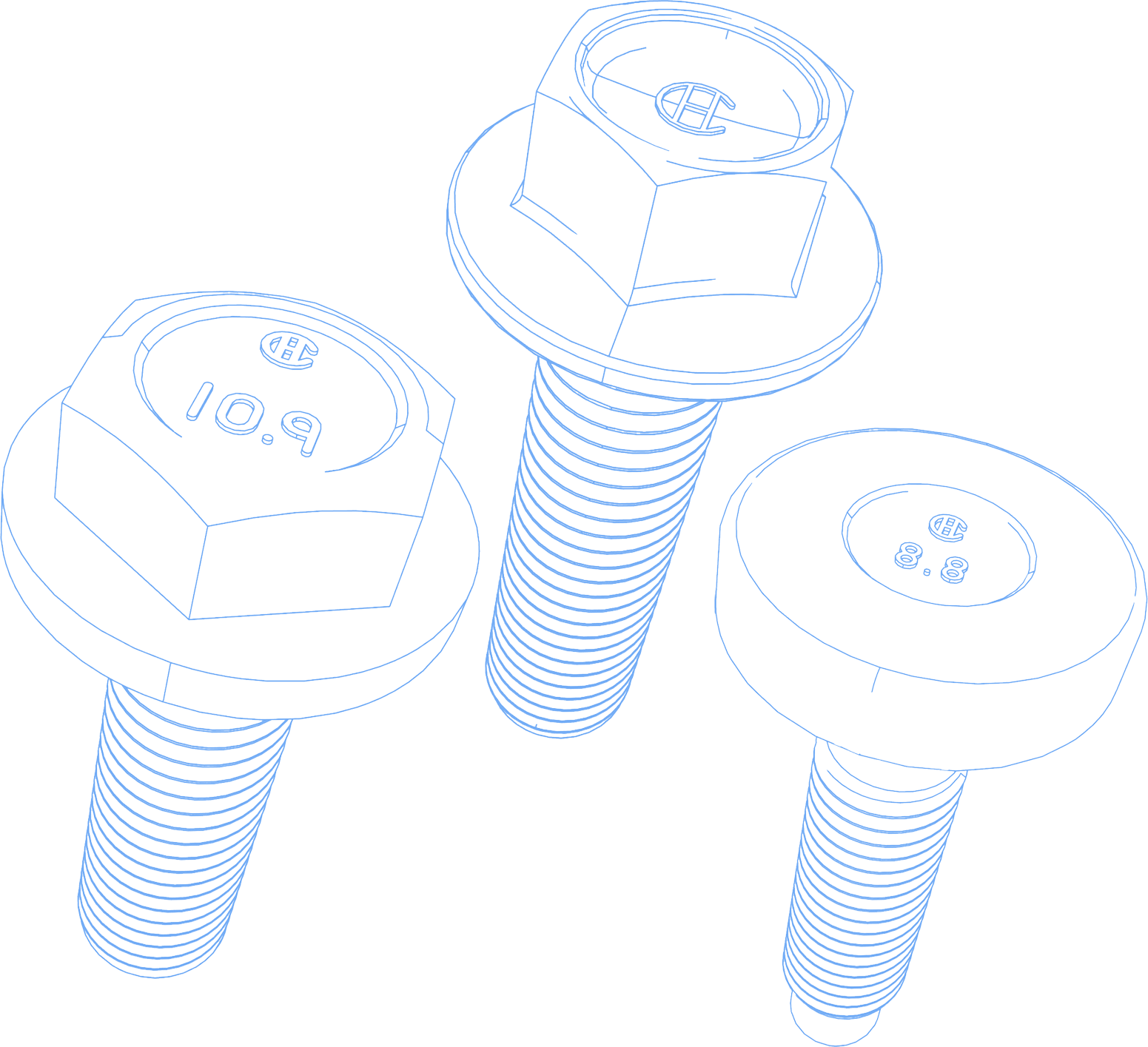

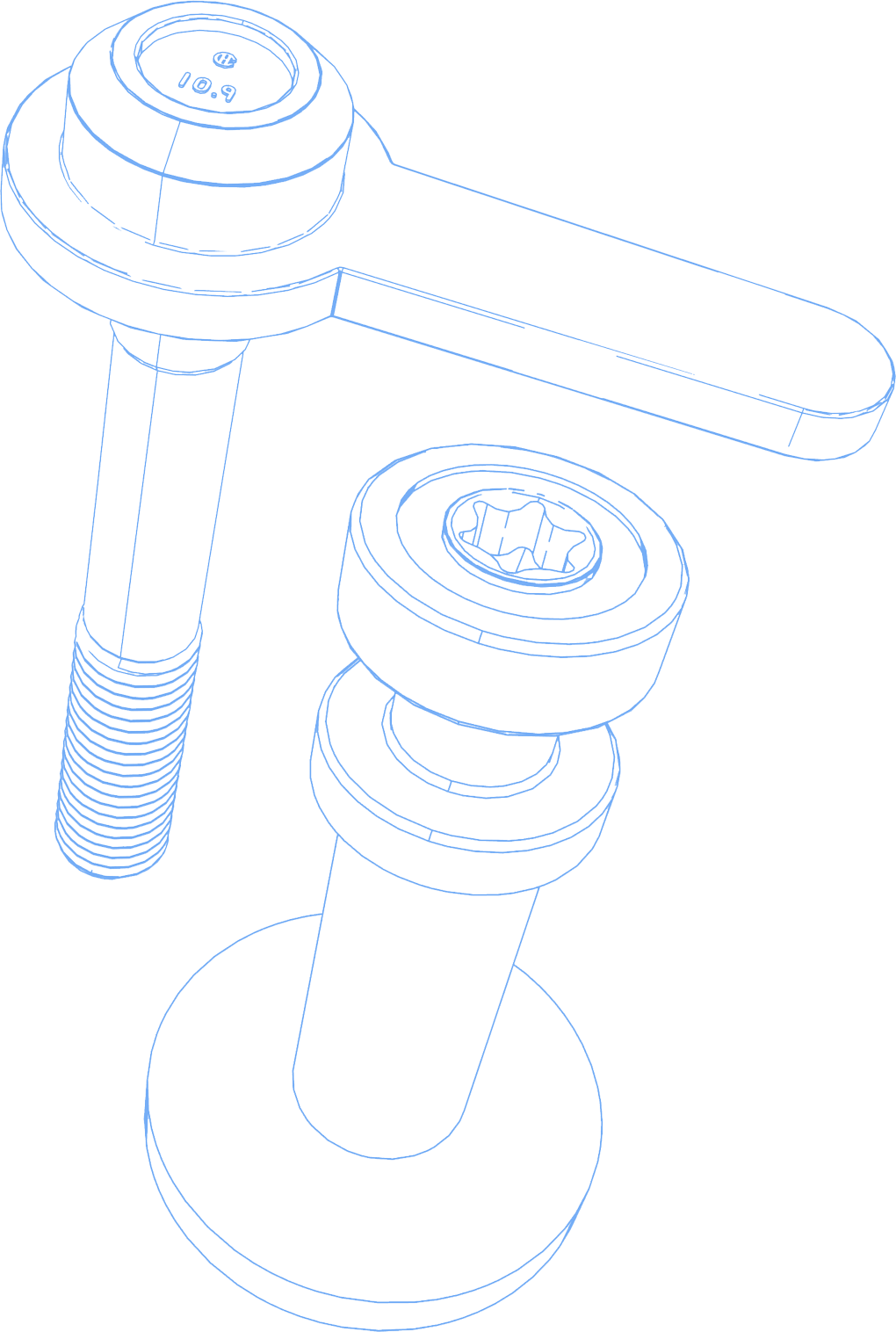

CHCs product range extends to nearly all applications in the automotive, commercial truck, agriculture & military industries. With the vertical integration of sub-processes CHC provides complete control of quality from start to finish for every fastener. CHC is a trusted source for the most critical applications from automotive seat belt bolts to advanced military components. All CHC fasteners are designed for specific applications and with quality processes independently defined to exceed all performance requirements.

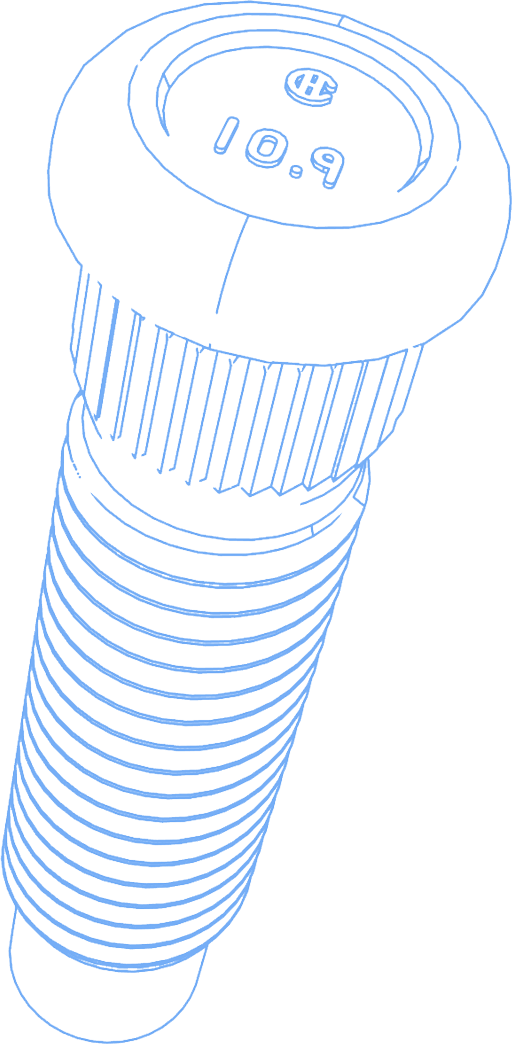

CHC has the capability of producing M6-M24 fasteners with lengths up to 350mm

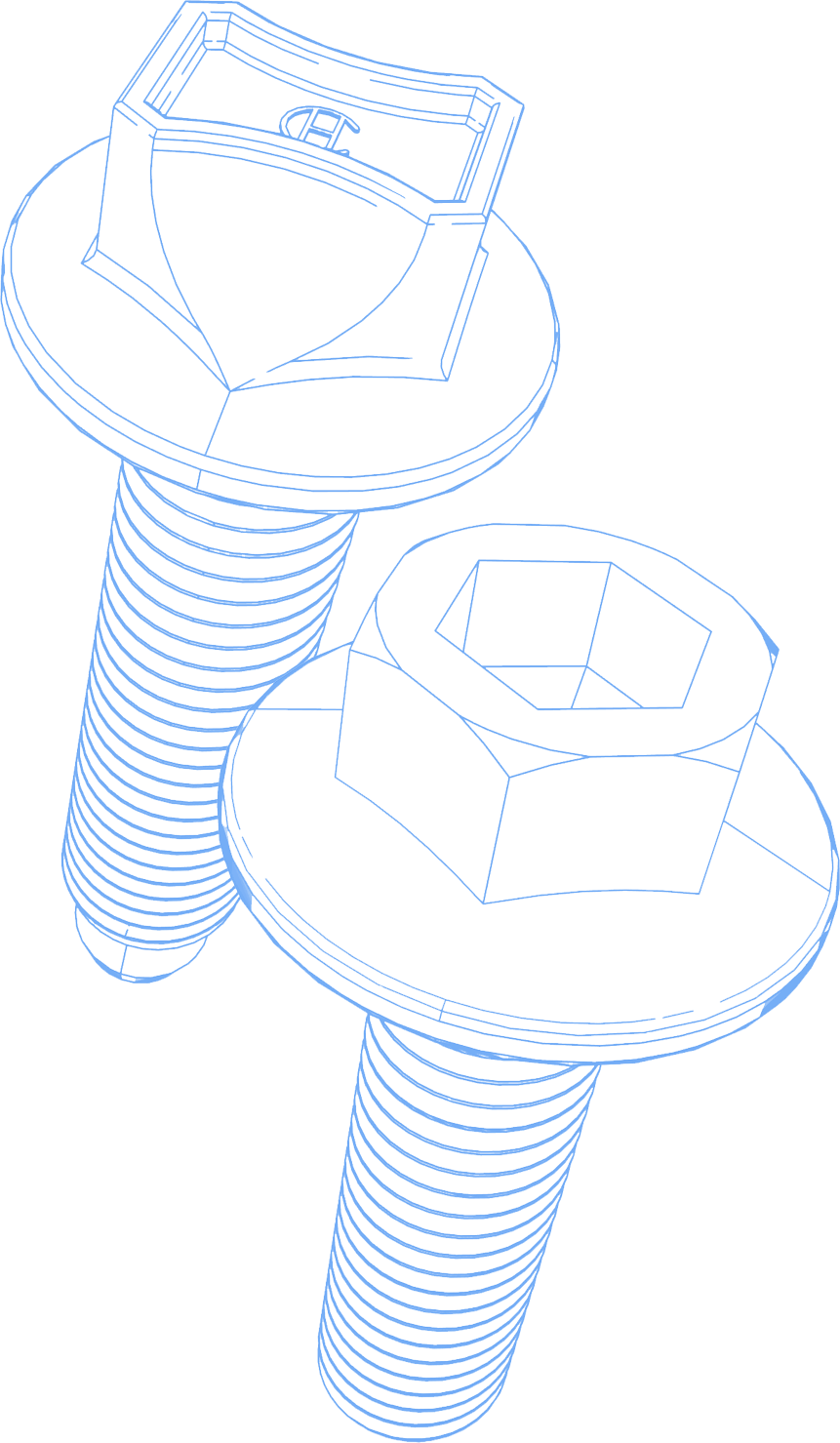

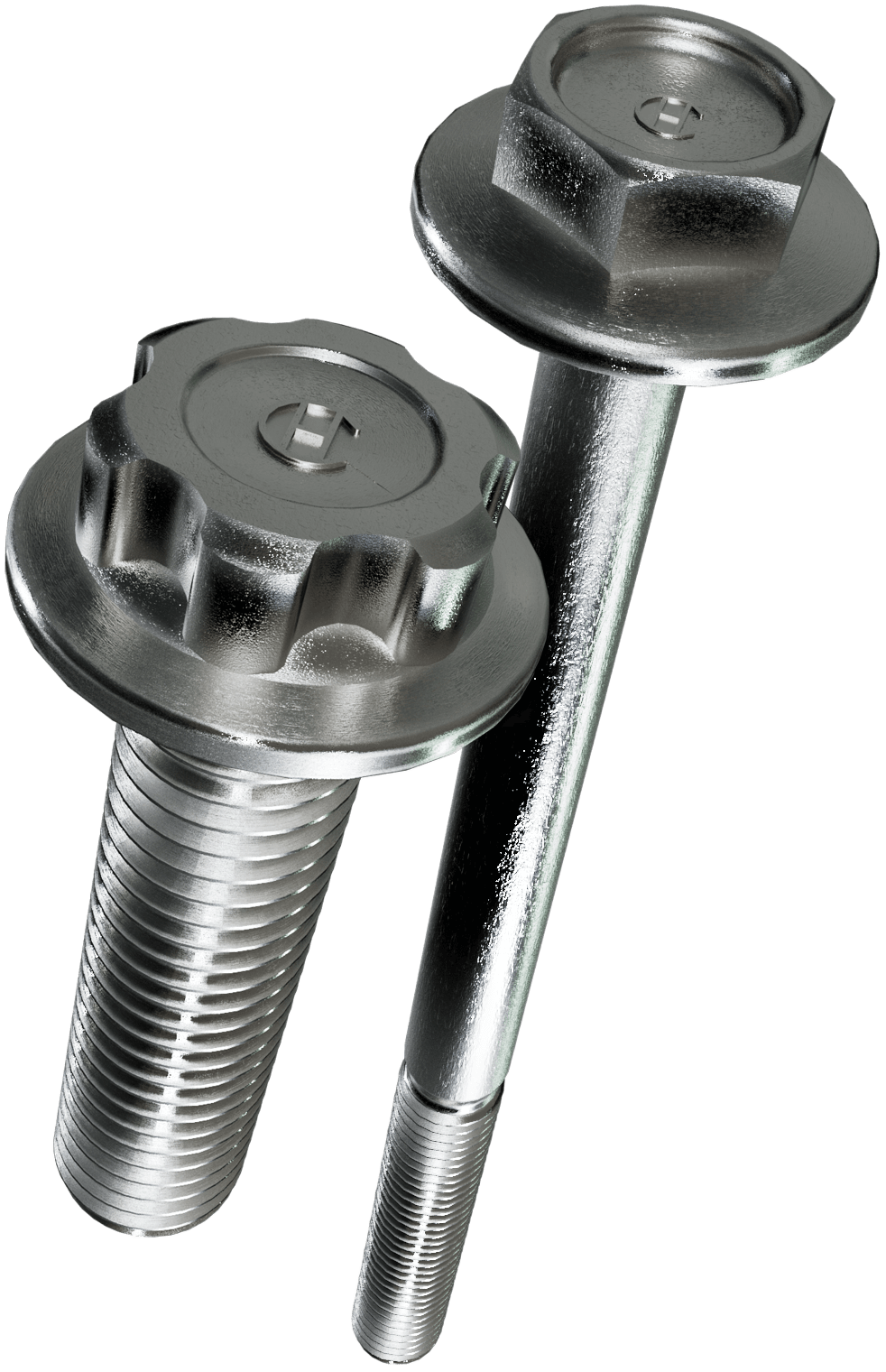

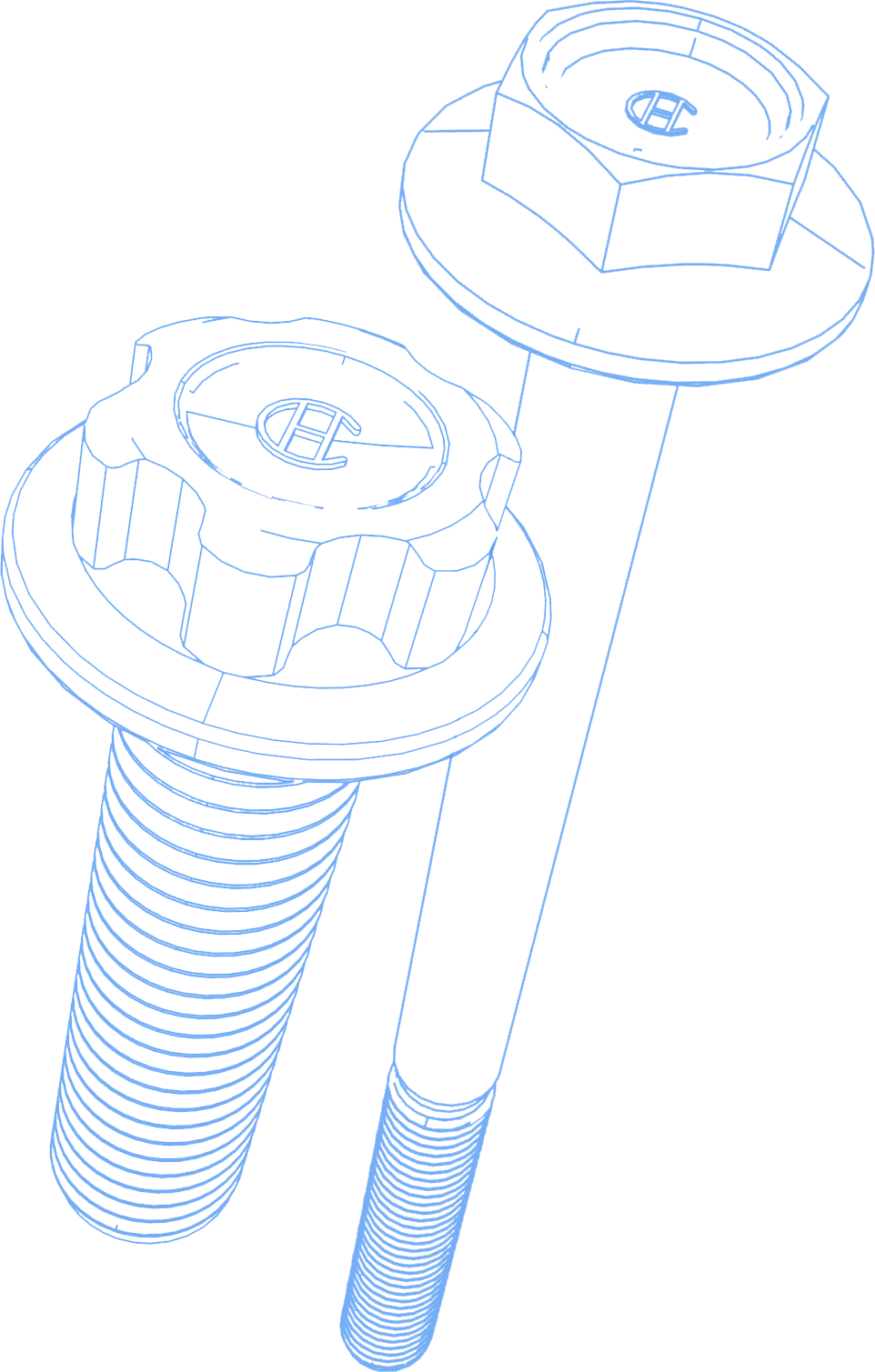

The push for electrification has seen an increased need for lightweighting solutions that has impacted the entire automotive industry. These demands also extend to automotive fasteners. CHC has developed several lightweight solutions that are proven in mass production such as deep recess head designs for applications where exposure is limited along with the 4HEX® Lightweight head design for critical chassis and exposed applications.

Electrification has driven further demands on traditional fasteners specifications. Aggressive lightweighting has resulted in reducing component & assembly packaging sizes which adds pressure to downsize fasteners while still maintaining high clamp load capabilities. These requirements have increased the proliferation of ultra-high strength steel fasteners beyond 12.9 property class to address these evolving demand needs.

CHC is a global leader in ultra-high strength fastener design and manufacturing with a range of proven applications in mass production.

CHC works with its customers’ engineering teams during the design process to offer effective cold formed solutions to meet any design challenges. Early design engagement & development is integral to ensuring efficient design solutions that improve feasibility, cost and quality.

CHC is the largest manufacturer of automotive wheel studs in North America. With decades of experience supplying this critical wheel application across all vehicle segments, CHC’s expertise and quality is unrivaled in the auto industry.

CHCs product range extends to nearly all applications in the automotive, commercial truck, agriculture & military industries. With the vertical integration of sub-processes CHC provides complete control of quality from start to finish for every fastener. CHC is a trusted source for the most critical applications from automotive seat belt bolts to advanced military components. All CHC fasteners are designed for specific applications and with quality processes independently defined to exceed all performance requirements.

CHC has the capability of producing M6-M24 fasteners with lengths up to 350mm